937-859-8503

937-859-8503

Roto-Grind

Roto-Grind

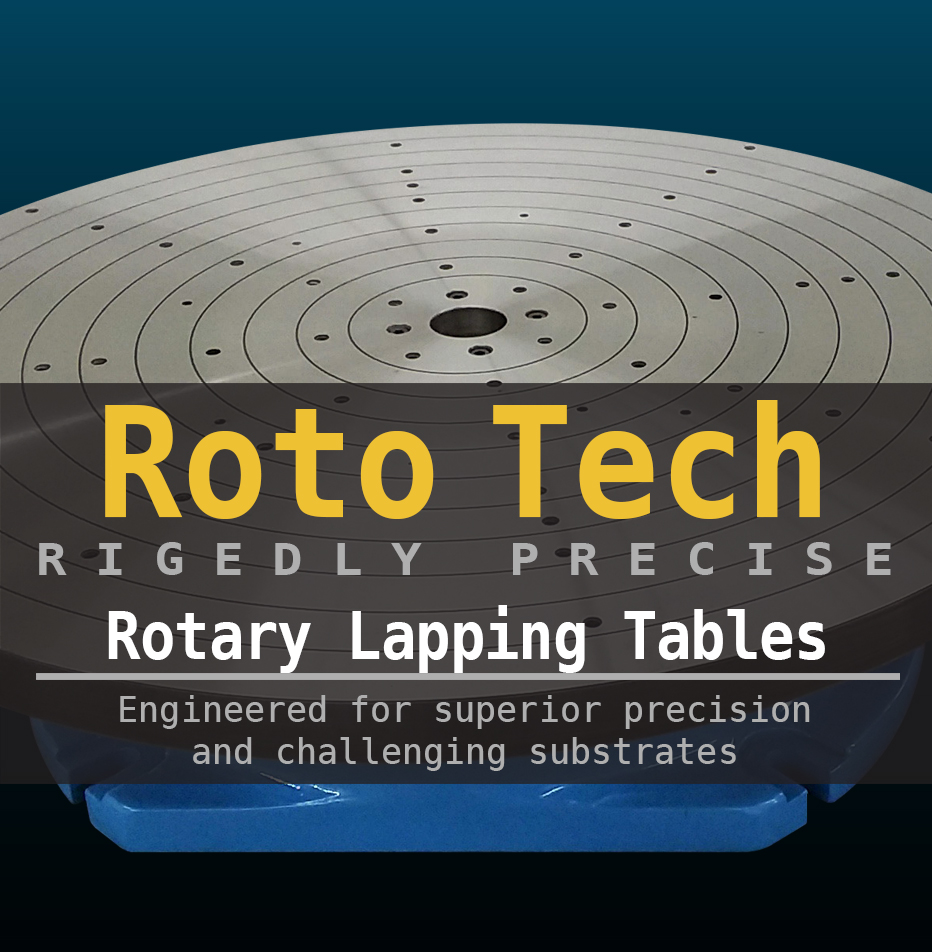

For precision rotary lapping, the Roto-Grind 1012HD from Roto Tech has remained the industry leader for rotary lapping on even challenging substrates like silicon, ceramic components and quartz. Performing ultra high precision rotary lapping requires a rotary table machine that is ultra rigid and stable.

Call Today for a Demonstration or Send Us a Note...

In some machining applications, lapping is one of the final finishing processes. While this accuracy is sufficient for many applications, grinding still leaves sub-surface cracks, or does not sufficiently penetrate the surface to the depths of the cracks made from prior processes. A precision Roto Grind rotary table attachment can improve this to 0.0001" on even brittle and challenging modern metallurgy.

There are a few lapping options available depending on the application. Virtually all lapping processes will provide a superior surface finish and at least some level of surface true-ness, but the level of accuracy will determine the appropriate apparatus. At the high-end are automated Lapping Machines, computerized systems with user interfaces, rigid rotating table, and hydraulic pressure plates. These machines are available in a wide variety of working diameter sizes and provide a high level of accuracy and piece throughput. At the low end, tabletop lapping plates are available for manual lapping applications. For a quick surface aesthetic improvement without the regard for surface true-ness, lapping mats can be an economical option.

Lapping Applications

In addition to a high-quality surface finish, the lapping process also provide a very effective way to achieve the ultra-true surface flatness needed for modern manufacturing processes. While typically associated with 2-D metal surfaces, lapping machines can be equally effective on curved and cylindrical objects in addition to a wide range of materials, from plastics to ceramics, making them a critical component in many industries.

Precision Rotary Tables used for lapping

The Roto Grind Precision Rotary Table used for lapping is a rigid cylindrical rotating table top. The rotary table is motor driven with variable rotation speeds to adapt to various lapped materials, lapping stages, and desired finish. The rigid base construction of a rotary table achieves greater stability and precision in the lapping process.