937-859-8503

937-859-8503

Roto-Grind

Roto-Grind

Performing ultra high precision rotary grinding requires a grinding machine that is ultra rigid and stable. The Roto-Grind 1012HD is engineered specifically for the most challenging and exacting specifications on the most difficult materials, including advanced ceramics.

Call Today for a Demonstration or Send Us a Note...

When most people think of ceramics they think of traditional, clay-based pottery. For nearly 20,000 years, humans have valued the strength ceramics provided and have been refining and perfecting ceramics for a wide range of uses, from refrigerator magnets to protecting spacecraft from re-entry.

Today, advanced, non-clay ceramics are being manipulated on the molecular level to provide specific solutions, even in highly volatile environments. In addition to achieving metallic strength, today's ceramics can maintain consistent performance levels under chemical, dimensional, thermal, electrical and mechanical duress. In the semiconductor industry, advanced ceramics are among the very few materials able to endure multiple cycles of extreme temperature swings, plasma and corrosive and reactive liquids and gasses of the ultra high precision production.

The moisture and corrosion resistant properties of ceramics make them ideal as implants in the medical and dental fields.

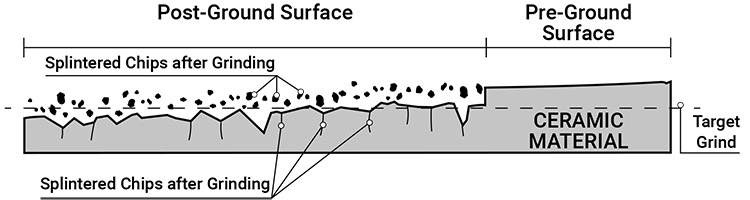

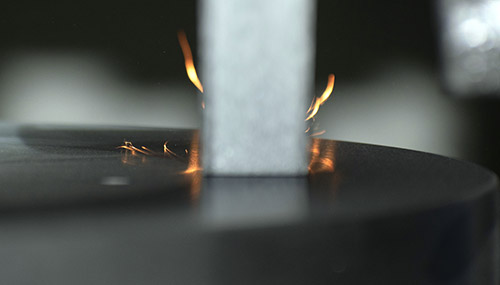

The strength and rigidity properties we value most of ceramics also make them particularly challenging to precision grind. In addition to being super hard, the crystalline structure of ceramics are brittle which results in a fractured surface following grinding. In this grinding process, small cracks form below the surface, but if too deep, the cracks can compromise the piece. Patience is critical, but so is the processing equipment.

Added to the difficulty in grinding ceramics is the advancement of grinding wheel technology. As ceramic formulas become more advanced and specific, so, too, must the grinding wheels. This adds greater emphasis on the grinding machine. Performing ultra high precision rotary grinding requires a grinding machine that is ultra rigid and stable. This enables the use of more exotic grinding wheels that are designed for harder materials.

That's why ceramic manufacturers and machine shops ask for Roto-Grind Precision Rotary Grinding Tables. Roto-Grind Rotary Grinding Tables are still built in the USA and maintains the same rugged and rigid craftsmanship as the first Roto-Grind in 1958.

Roto-Grind Precision Rotary Grinding Tables were originally engineered to tackle ultra hard materials. Even as manufacturing and processing have become more advanced, technical and extreme, Roto-Grind has consistently delivered solid results.

Some of the material for this article was collected from:

Science Learn | The Ceramic Industry | CTE Magazine

Made in the USA

Every Roto-Grind Rotary Grinding Table features premium quality components and craftmanship from our Dayton, Ohio facility. |

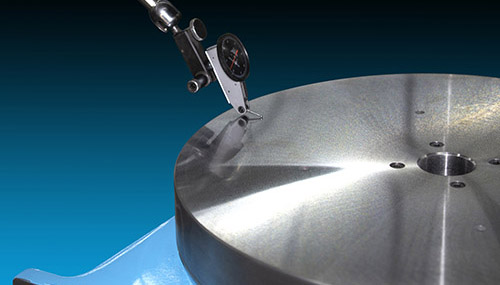

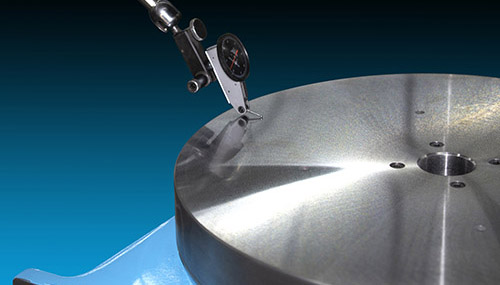

Achieving Perfection

We meticulously analyze every detail in the construction of a Roto-Grind Rotary Grinding Table for premium performance. |

Ready for Shipment

These Rotary Grinding Tables are finely-tuned and ready to ship to North America, Europe and Asia component manufacturers. |

Made in the USA

Every Roto-Grind Rotary Grinding Table features premium quality components and craftmanship from our Dayton, Ohio facility. |

Achieving Perfection

We meticulously analyze every detail in the construction of a Roto-Grind Rotary Grinding Table for premium performance. |

Ready for Shipment

These Rotary Grinding Tables are finely-tuned and ready to ship to North America, Europe and Asia component manufacturers. |