937-859-8503

937-859-8503

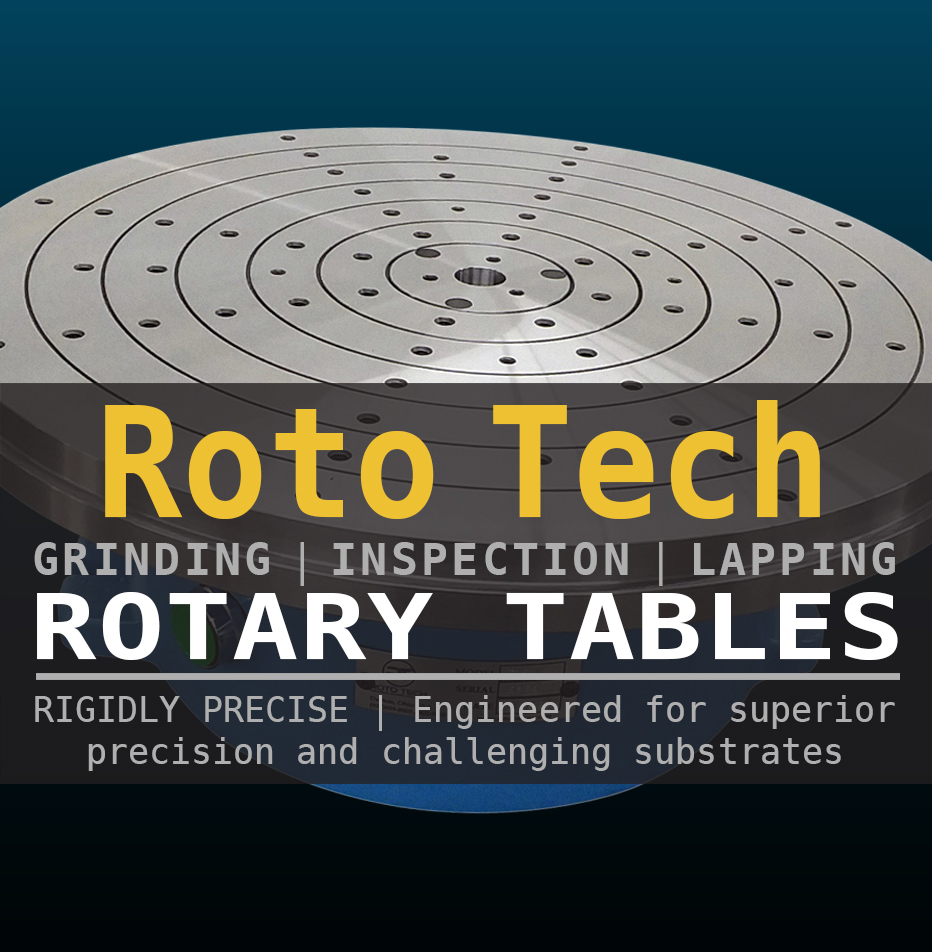

Roto-Grind | Roto Tech

Roto-Grind | Roto TechRoto Tech's Roto-Grind Rotary Grinding Table is the ideal accessory for your machine shop. In addition to increased precision, Roto-Grind Tables greatly enhance your machines versatility.

|

|

|

|

|

|

Accessorize your machine shop with Roto Tech Rotary Grinding Tables. Roto-Grind Tables maximize precision machining and enhances machine versatility.

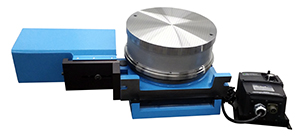

Sine Grinding

Sine Grinding

Roto Tech Rotary Grinding Tables are available with sine grinding capabilities.

Magnetized Chuck

Magnetized Chuck

A magnetized chuck provides easier, more precise placement and work piece access.

Magnetized Chuck

Magnetized Chuck

A magnetized chuck provides easier, more precise placement and work piece access.

Every machine in a job shop represents a significant investment for the business. Before proceeding, the business likely analyzes various industry and customer inputs in relation to the cost and attempts to project the expected return on investment the increased capabilities should generate.

In addition to the financial output, a new machine may require some "break-in" time. Shop workers likely need to learn the new machine's operation and capabilities, perhaps even to the point of additional training, or even hiring of specialized staff.

The other consideration may be space. Most CNC machines won't fit snuggly in the corner and considerations must be made for integrating the machine into the existing work flow structure on the production floor.

MACHINE SHOP ACCESSORIES

Once the machine has been purchased, the buyer is often presented with a variety of accessories to enhance and extend the capabilities of the machine. Third-party manufacturers have, as well, developed an array of accessories to integrate with many of these machines to offer an even greater capabilities.

SURFACE GRINDING MACHINE ACCESSORIES

One of the most common machines in a machine shop is the Surface Grinder. The rotating abrasive disk provides a smooth finish to exact tolerances to a variety of materials. Read more...