937-859-8503

937-859-8503

Roto-Grind

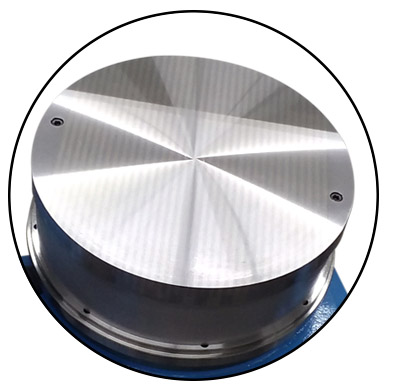

Roto-GrindRoto Tech's Roto-Grind Rotary Grinding Table is the ideal accessory for your machine shop. In addition to increased precision, Roto-Grind Tables greatly enhance your machines versatility.

|

|

|

|

|

|

Accessorize your machine shop with Roto Tech Rotary Grinding Tables. Roto-Grind Tables maximize precision machining and enhances machine versatility.

Sine Grinding

Sine Grinding

Roto Tech Rotary Grinding Tables are available with sine grinding capabilities.

Magnetized Chuck

Magnetized Chuck

A magnetized chuck provides easier, more precise placement and work piece access.

Motorized Table

Motorized Table

Rotary table motor provides greater production efficiency and available in 0.5 and 0.75 horsepower.

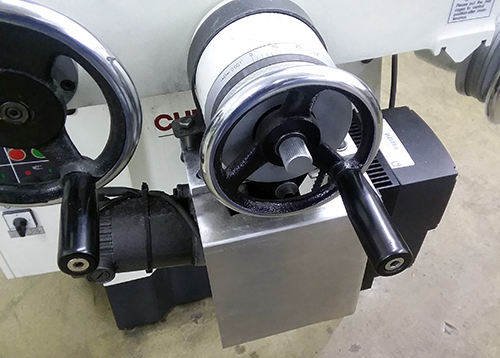

Surface Grinder Cross Axis Retrofit Kit

Surface Grinder Cross Axis Retrofit Kit

Roto-Grind surface grinder retrofit kit for power feed on your cross-feed axis. Includes motor gearbox, pulley, belt, cover and control mounted to motor cover with 6' power cord for 120 VAC, 60 cycle, 1 phase. Kit allows for power feeding of cross axis in either direction at a variable speed.

The Surface Grinder is the most common of the finishing machines in the average machine shop. The Surface Grinder puts a high quality finish on a variety of substrates with tolerances achieving upward of 1/10,000". This utilitarian machine provides a lot of solutions, not the least of which for sharpening and finishing other tools around the shop.

Whether the surface grinder has a horizontal or vertical spindle, it starts with the grinding wheel. A wide array of grinding wheels are available depending on, for instance, the material being worked, the desired geometry or finish, and the size of the piece. Grinding wheels not only vary by size and width, they also vary by grain weight (fine to course), composition, including diamond, aluminum oxide, ceramic, and more, and the bonding material holding the abrasive elements. In some finishing processes, a coolant system can be installed to improve quality by maintaining better surface integrity in high heat grinding applications.

The work piece, or pieces, is positioned on the surface grinder work table, located beneath the grinding wheel. Most Surface Grinder work tables are capable of moving in XYZ axis either manually or with an integrated computer guidance system. A work table with Sine capabilities provides the ability to swing the table to achieve more difficult angular geometries.

To secure the work piece in place, there are a number of chucks, vices and grips available. Magnetic table chucks are also available and offers quick precision placement without an impeading vice or clamp.

Combining the two together, some shops also use a magnetic rotary chuck, or rotary grinding table with magnetic chuck. Secured to the Surface Grinder work table, a magnetic rotary table with sine capability can eliminate the need for a separate dedicated machine to achieve higher tolerance geometries, including inside and outside diameter and cylindrical grinding. Rotary grinding tables are also commonly relied on for the lap finishing process.

As with many large machines across multiple industries, the more up-time they have, the quicker the investment pays off and accessories can move those metrics quicker.